purelyft energized - your drinks with clean caffeine

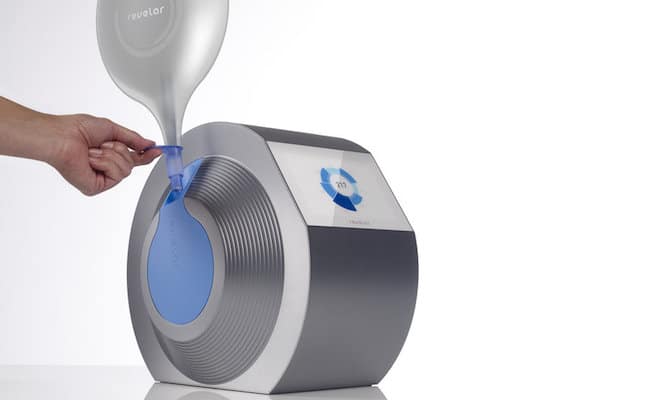

We began with the production, developed a disposable and finally developed a machine to bag the package.

The triangular shaped Disposable is filled with pure caffeine in powder form, thereafter it is filled and sealed. For simple handling, the disposable is perforated on one side, so that the caffeine can mix in with the drink while stirring. This opening is sealed before use by label.

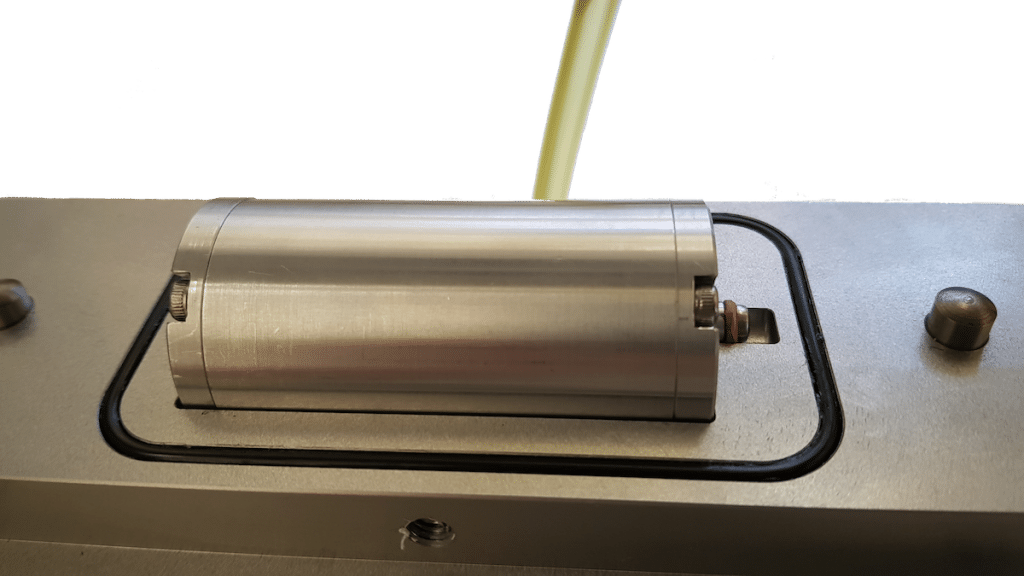

The production is carried out with a rotary transfer machine. The machine picks up two products at a time in the product carrier, fills them and closes them with a lid. Subsequently, the product is handed over to the bag machine, which forms and closes a stickpack around the product.